3D Printing Techniques

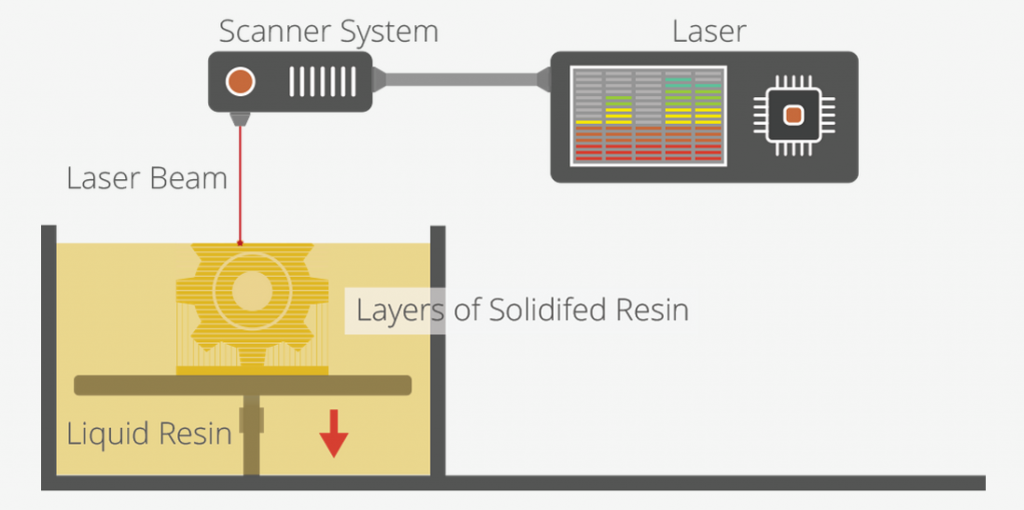

Stereolithography (SLA)

Stereolithography is an additive manufacturing process using a vat of liquid UV-curable photopolymer ”resin” and a UV laser to build parts a layer at a time.

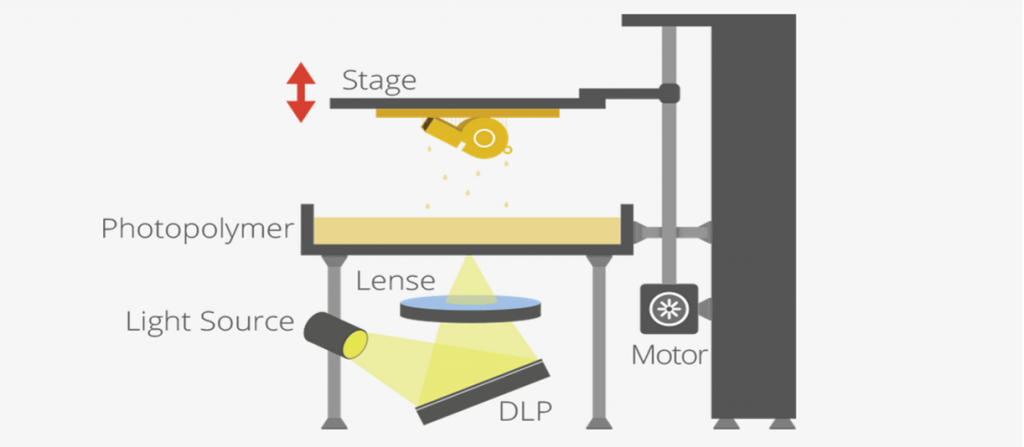

Digital Light Processing (DLP)

Digital Light Processing displays the image of the 3D model onto the liquid polymer. The exposed liquid polymer hardens and the build plate moves down and the liquid polymer is once more exposed to light. The process is repeated until the 3D model is complete and the vat is drained of liquid, revealing the solidified model.

Selective Laser Sintering (SLS)

Selective Laser Sintering is an additive manufacturing technique that uses a high power laser (for example, a carbon dioxide laser) to fuse small particles of plastic, metal (direct metal laser sintering), ceramic or glass powders into a mass that has a desired 3-dimensional shape.

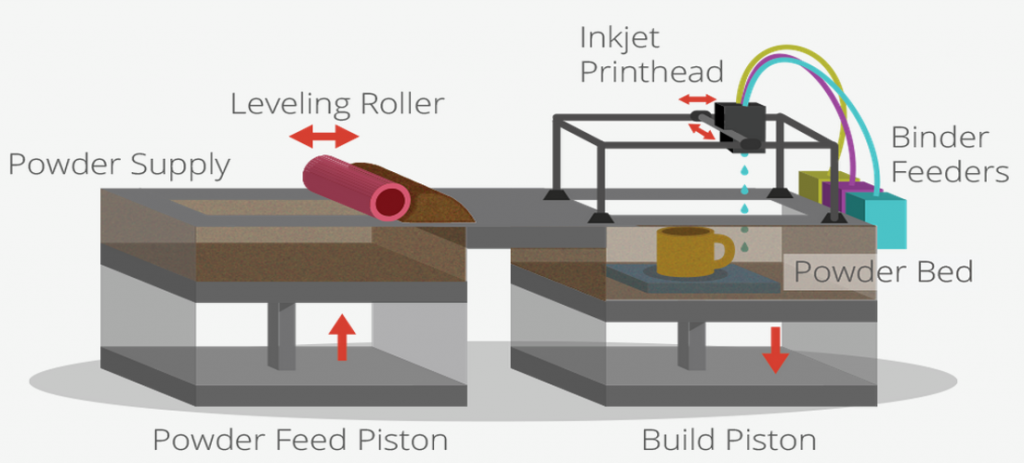

Inkjet : Binder Jet

A binder jetting machine will distribute a layer of powder onto a build platform. A liquid bonding agent is applied through inkjet print heads bonding the particles together. The build platform will be lowered and the next layer of powder will be laid out on top. By repeating the process of laying out powder and bonding, the parts are built up in the powder bed.

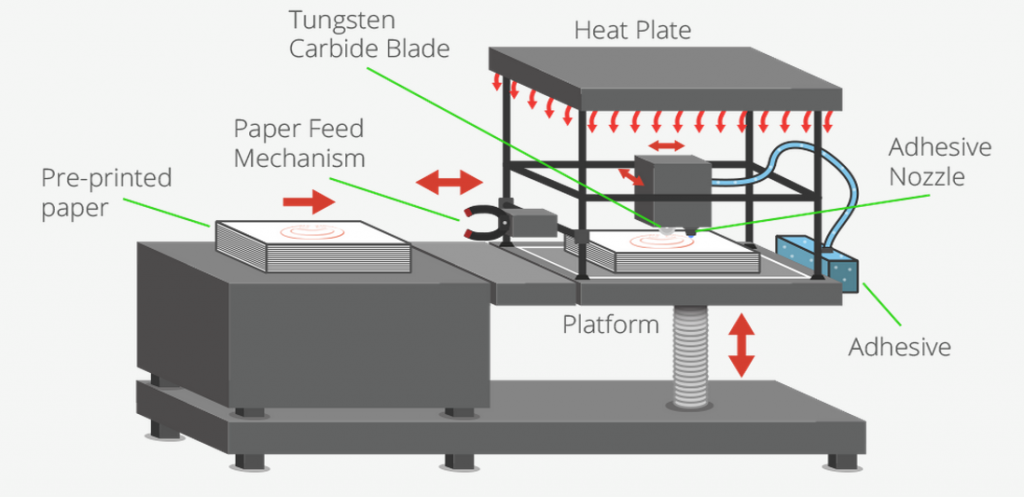

Selective Deposition Lamination(SDL)

Selective Deposition Lamination is a 3D printing process using paper. The process involves layers of adhesive coated paper (or plastic or metal laminates) that are successively glued together with a heated roller and cut to shape with a laser cutter layer by layer. A roller with the material moves each new sheet of material over the last and repeats the process until the object is completed.

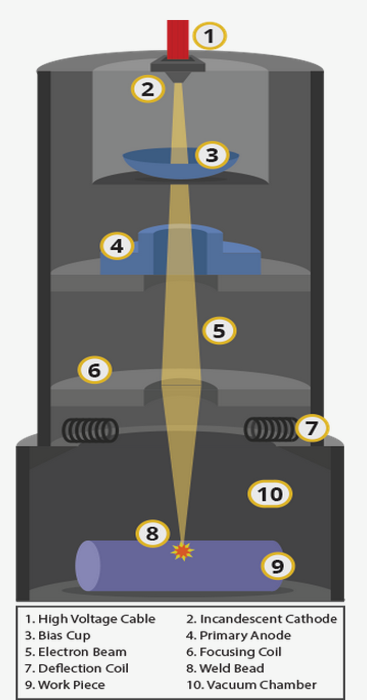

Electronic Beam Melting (EBM)

Electron Beam Melting is similar to laser melting, but working with an electron beam instead of a laser. The machine distributes a layer of metal powder onto a build platform, which is melted by the electron beam. The build platform is then lowered and the next layer of metal powder will be coated on top. The process of coating powder and melting where needed is repated and the parts are built up layer by layer in the powder bed.

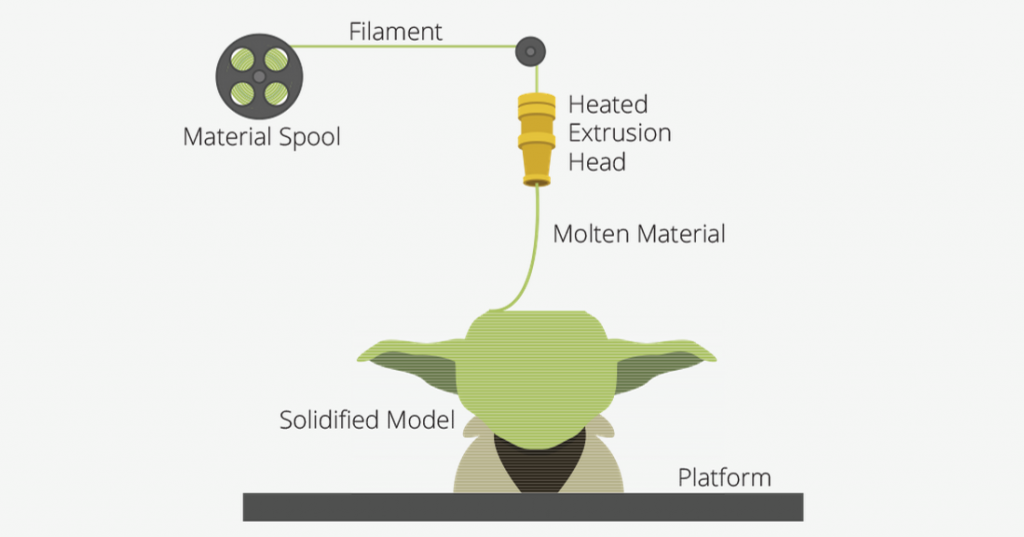

Fused Filament Fusion (FFF)

Fused Filament Fabrication is an additive manufacturing technology, it’s now the most popular 3D printing process, and in FFF a continuous filament of a thermoplastic material is used. Through a moving, heated printer extruder head, molten material is forced out of the print head’s nozzle and is deposited on the work piece Layer by layer to form the desired Product.